About PTFE

Home Products

Home Products

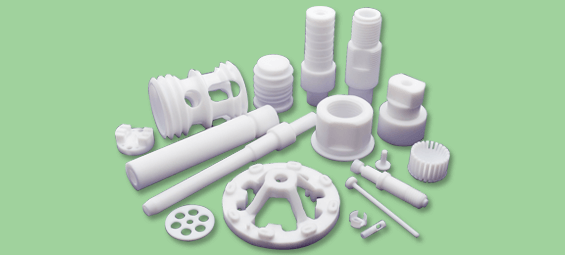

PTFE stands for POLY TETRA FLUORO ETHYLENE, which is the chemical term for the polymer (CF2) n. PTFE is a thermoplastic member of the fluoro polymer family of plastics. PTFE has a low coefficient of friction, excellent insulating properties, and is chemically inert to most substances. It also can withstand high heat applications and it is well known for its anti-stick properties.

Applications

The uses and applications of PTFE have grown enormously over the past 70 years. probably one of the most famous uses of PTFE is as a non-stick coating found on cookware. However, PTFE is used in the semiconductor, medical, chemical, automotive, electrical, aerospace, filtration, wire & cable as well as petrochemical industries.

Chemical processing and petrochemical sectors : Used for vessel linings, seals, spacers, gaskets, well-drilling parts and washers, since PTFE is chemically inert & resistant to corrosion.

Laboratory Applications : Tubing, piping, containers & vessels due to resistance to chemicals & absence of contaminants attaching to the surface of PTFE products.

Electrical Industry : Used as an insulator in the form of spacers, tubing & the like Virgin PTFE had been approved by the FDA for use in the pharmaceutical, beverage, food and cosmetics industries in the form of conveyor components, slides, guide rails, along with other parts used in ovens and other heated systems.

Semiconductor Sector : Used as an insulator in the production of discreet components such as capacitors and in the chip manufacturing process.

Fillers : In many instances PTFE in its purest form is a perfect solution. However, when an application demands a modification to the basic PTFE chemistry, Plastomer Technologies can help satisfy a broader range of physical, thermal, or practical demands.

Examples include glass or bronze fillers for added stiffness & strength, carbon fillers for conductivity, & moly blends for added lubricity.